Engineering Leaders must continuously evolve their processes, organisation and management systems to address the challenges that arise during a company’s lifecycle; such as managing growth, more projects, staying innovative, adopting new technologies, supporting installed base and controlling the supply chain.

In engineering businesses, finding the equilibrium between managing daily operations and focusing on continuous improvement initiatives is undeniably challenging. By identifying prevalent indicators that signify the necessity for changes, companies can significantly enhance their progress and operational effectiveness by eliminating time wastage.

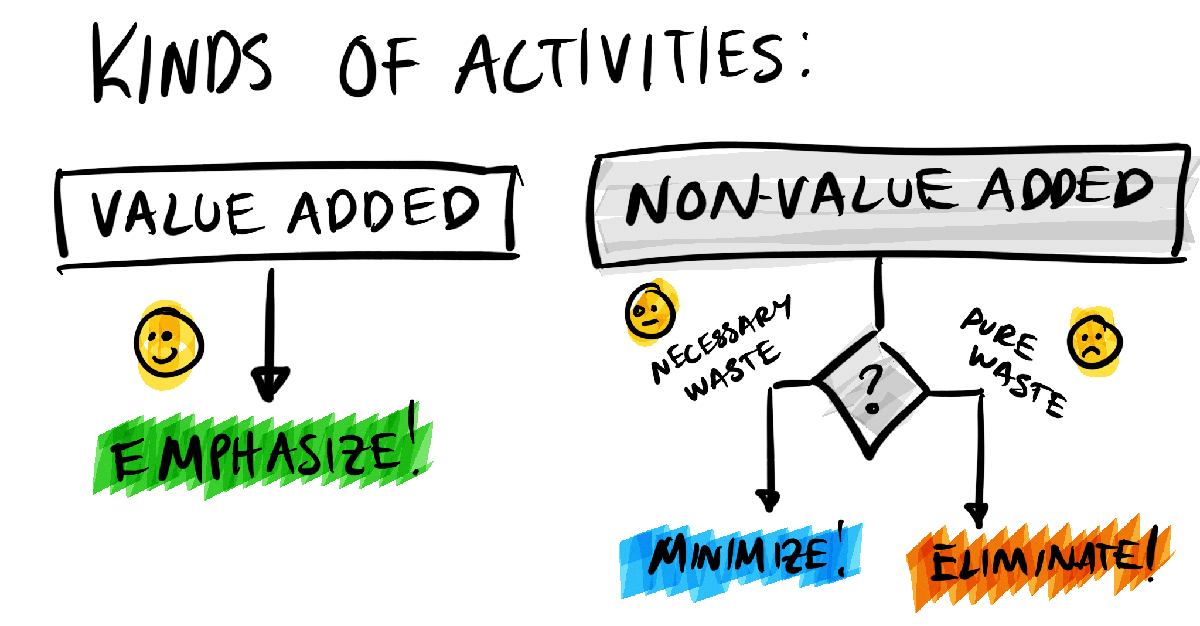

Non-Value-Added time, which can consume approximately 20-40% of project durations due to involvement in activities with limited value, often contributes to project delays. Enhancing existing processes not only diminishes waiting periods but also elevates overall project efficiency levels.

Typical Issues

-

Constant interruptions

Changing Priorities

Lack of resources

Over-Engineering

Re-inventing the wheel

Requirements missing

Waiting for decisions

Slow processs

Late design loopbacks

Supplier issues

Cross functional collaboration

Wasteful meetings

Manufacturing issues

Unnecessary steps

Yes, late delivery or not meeting requirements can be problematic for businesses across various sectors. It could significantly impact essential aspects such as customer satisfaction, sales performance, revenue generation, market share, and in the long run, even the competitive strength of the company. These consequences highlight the critical importance of timely delivery and meeting the specified requirements to ensure sustained business success.

Is this a problem?

Indeed. Delays in projects are not a law of nature. We just need to identify the underlying issues, address them, and establish better practices.

Lean product development is a systematic and effective approach to achieve this. Whether you're addressing existing problems or striving for excellence ahead of others, Lean principles and tools empower you to deliver faster and more efficiently. Additionally, they promote a culture of always learning. Lean isn't expensive or complicated, and it almost surely leads to success. You just need creativity and commitment.

This forms the foundation of a compelling business case!